Precision metal machining plays a vital role in the machinery manufacturing sector, providing high-accuracy components that ensure performance, durability, and efficiency in industrial equipment.

Gear & Transmission Components

High dimensional accuracy, wear resistance, and smooth operation for power transmission systems.

Hydraulic & Pneumatic Parts

Valve bodies, cylinders, pistons, and manifolds

Tight tolerances and leak-proof performance for fluid and gas control systems.

Industrial Machinery Frames & Housings

Machine bases, enclosures, and structural supports

Robust construction with precise alignment for stability and vibration resistance.

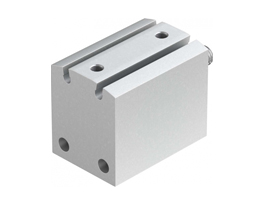

Custom Tooling & Fixtures

Jigs, molds, dies, and clamping systems

High repeatability and durability for mass production and assembly processes.

Precision Engineered Components

Linear guides, spindles, couplings, and actuators

Optimized for high-speed, high-load, and long-term reliability in automated systems.

Why Choose Precision Metal Machining for Machinery Manufacturing?

✔ High Accuracy & Consistency – Ensures seamless assembly and operation of complex machinery.

✔ Material Versatility – Supports stainless steel, aluminum, titanium, and alloy steels.

✔ Advanced Processes – Combines CNC turning, milling, grinding, and EDM for superior finishes.

✔ Custom Solutions – Tailored machining for prototypes, small batches, and large-scale production.

Precision metal machining is indispensable in the machinery industry, delivering high-performance components that enhance equipment efficiency, longevity, and operational precision. By leveraging advanced machining techniques, manufacturers can achieve superior quality and reliability in industrial machinery production.