Precision manufacturing technologies play a vital role in today's consumer goods production, delivering both functionality and aesthetic appeal through four key processes:

Sheet Metal Fabrication

Transforms flat metal sheets into durable consumer products including:

Appliance housings for kitchen and home electronics

Structural components for modern furniture

Decorative architectural elements

This versatile process combines design flexibility with structural integrity, enabling both mass production and custom solutions.

CNC Machining

Delivers precision-engineered components for:

High-tech electronics and smart devices

Precision kitchen appliance mechanisms

Personal care and wearable technology

With micron-level accuracy, CNC machining ensures reliable performance in consumer products requiring tight tolerances.

Injection Molding

Dominates plastic consumer goods manufacturing for:

Food storage containers and packaging solutions

Children's toys and educational products

Household items and cleaning tools

This high-volume process provides cost-effective production of intricate plastic parts with consistent quality.

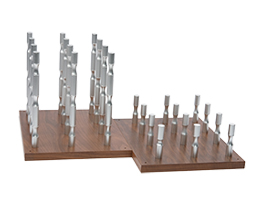

Metal Stamping

Produces essential metal components including:

Hardware and fastening systems

Decorative trims and accents

Small appliance parts

Offering unmatched production speed, stamping is ideal for high-volume consumer goods manufacturing.

These advanced manufacturing methods collectively enable brands to deliver innovative, high-quality products that meet evolving consumer expectations while maintaining competitive production costs. From concept to finished product, these technologies form the backbone of modern consumer goods manufacturing.