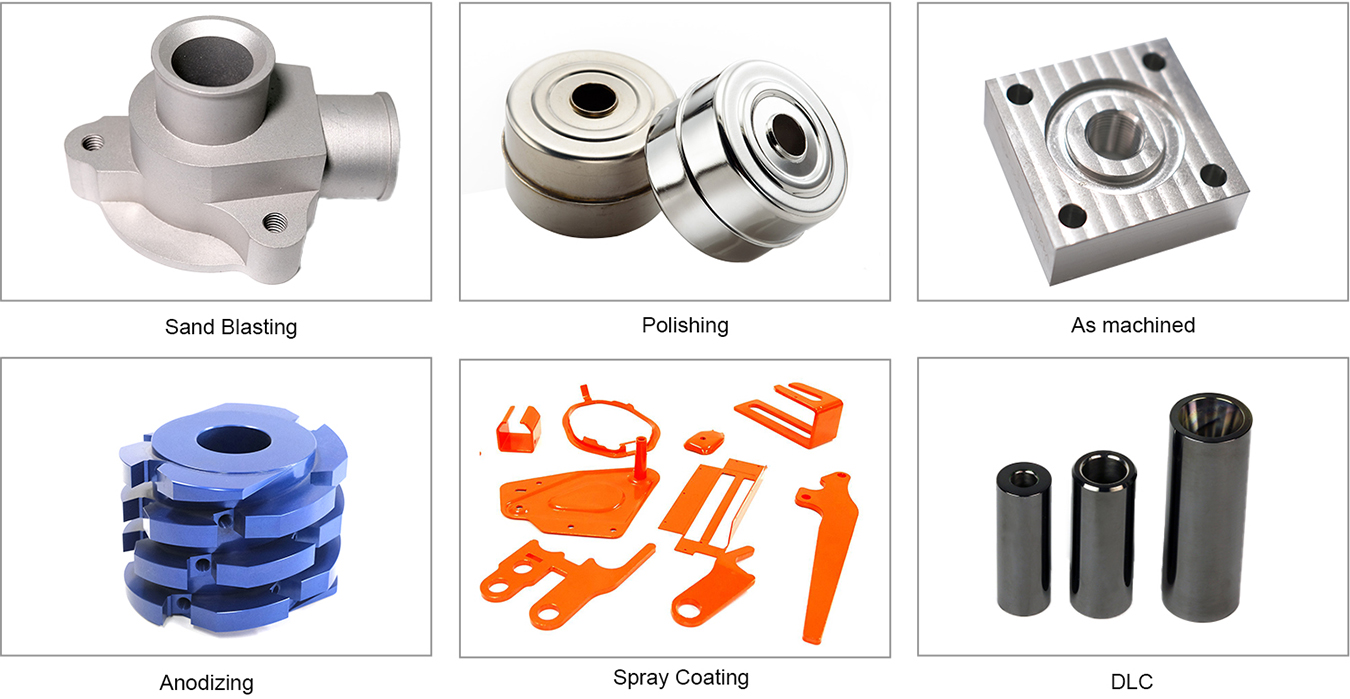

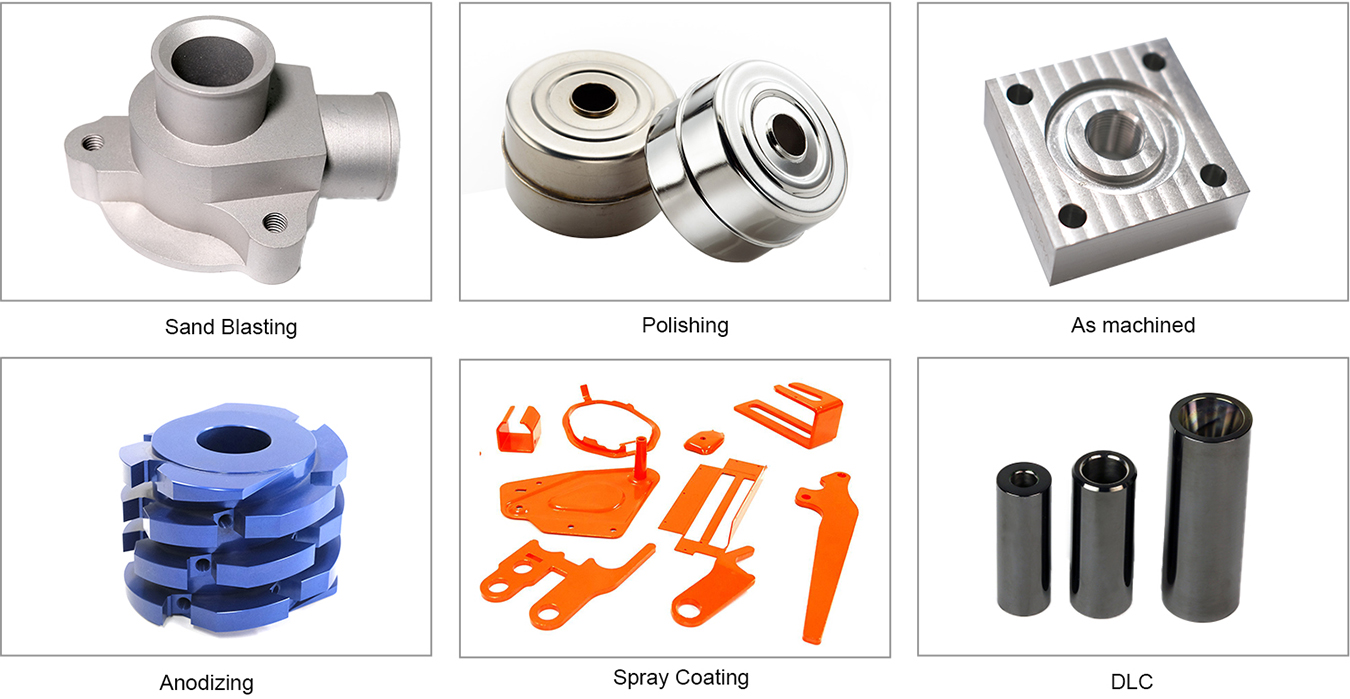

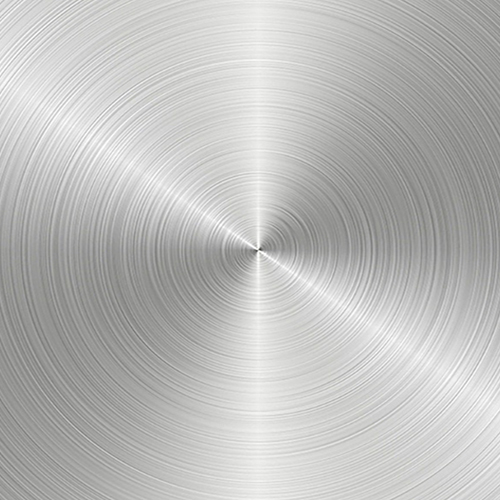

For metal machining parts, more commonly used surface treatment methods are mechanical grinding, chemical treatment, surface heat treatment, spray surface, surface treatment is the surface of the workpiece cleaning, cleaning, deburring, to oil, descaling and so on.

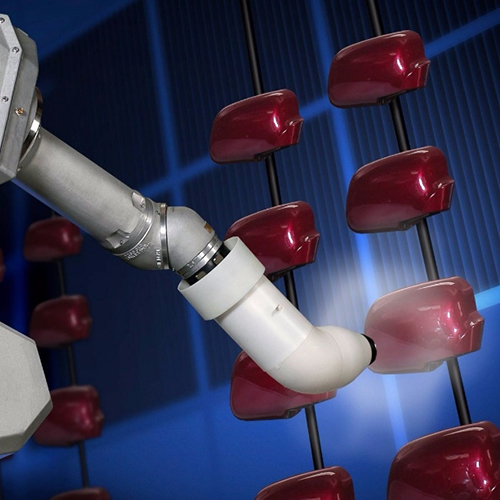

Polishing refers to a processing method that uses mechanical, chemical or electrochemical effects to reduce the surface roughness of a workpiece to obtain a bright and smooth surface.

The process of using the impact of high-speed sand flow to clean and roughen the substrate surface.

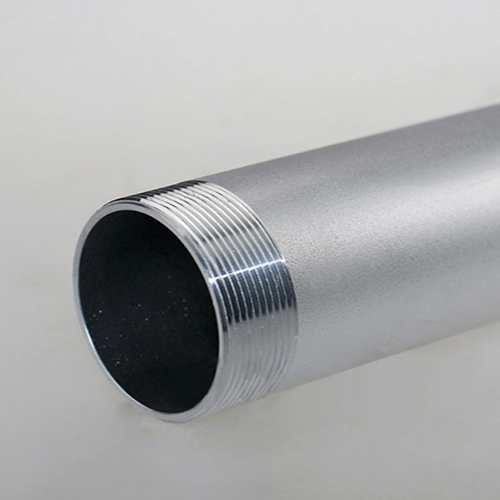

A surface treatment method that forms lines on the surface of the workpiece by grinding the product to achieve a decorative effect.

It is the process of plating a thin layer of other metals or alloys on certain metal surfaces using the principle of electrolysis.

Spraying is a coating method that uses a spray gun or a disc atomizer to disperse the liquid into uniform and fine droplets with the help of pressure or centrifugal force and apply it to the surface of the object.

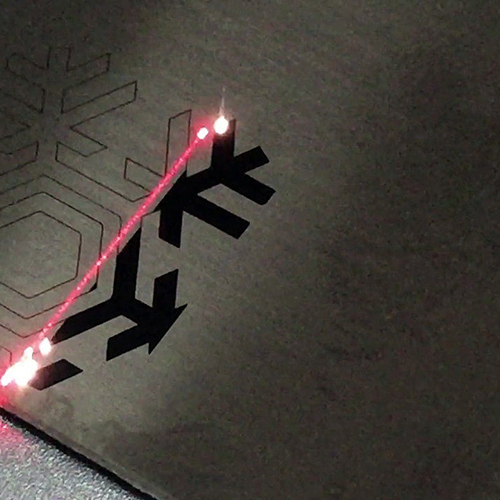

Also known as laser engraving or laser marking, it is a process that uses optical principles to perform surface treatment.

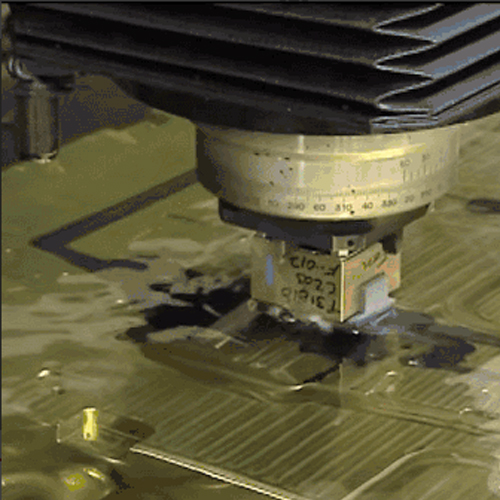

Electrospark machining is a special machining method that uses the electro-erosion effect generated by pulse discharge between two electrodes immersed in a working fluid to remove conductive materials. It is also called discharge machining or electro-erosion machining.

An electrolytic oxidation process during which the surface of aluminum and aluminum alloys is usually converted into an oxide film that has protective, decorative and other functional properties.

Electrophoresis can give various colors to the surface of the workpiece. The process is divided into anodic electrophoresis and cathode electrophoresis.

It refers to the use of low-voltage, high-current arc discharge technology under vacuum conditions, using gas discharge to evaporate the target material and ionize both the evaporated material and the gas, and using the acceleration effect of the electric field to deposit the evaporated material and its reaction products on the workpiece.