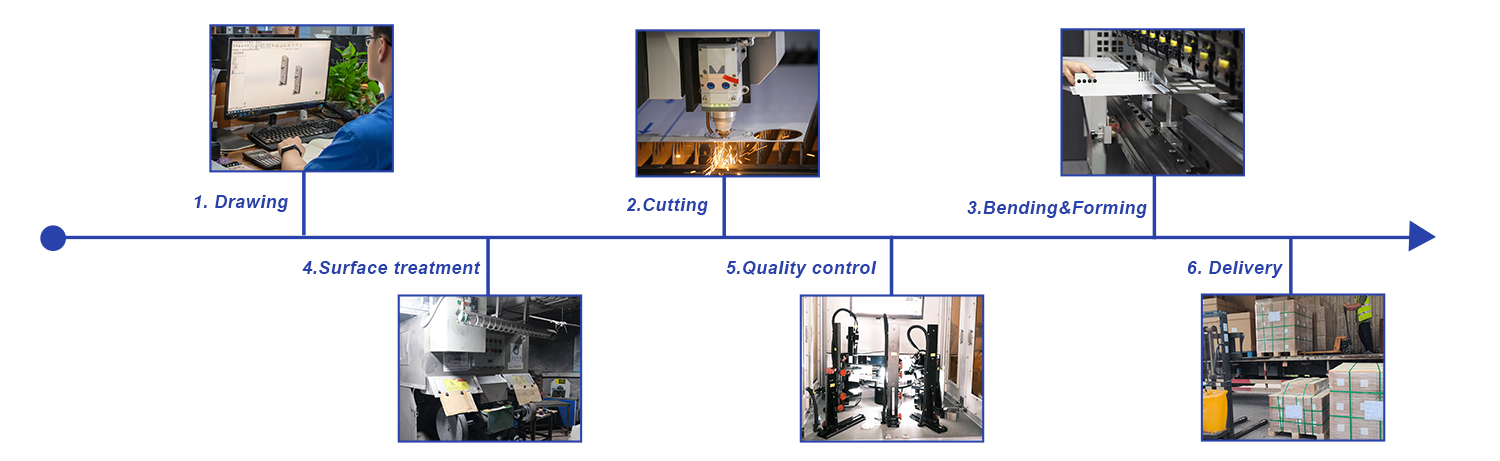

Professional Sheet Metal Fabrication – Utilizing CNC punching, laser cutting, and precision bending, we customize stainless steel, aluminum, and other materials with tight tolerances (±0.1mm) for aerospace, industrial equipment, and high-demand applications.

Full-service solutions from design optimization to mass production, ensuring cost efficiency and superior quality.

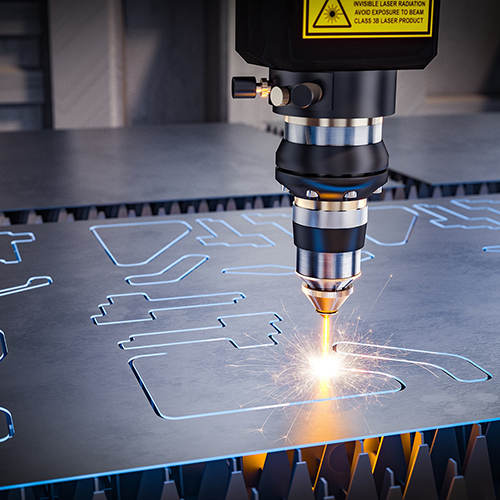

Sheet metal can be precisely shaped and sized through multiple cutting techniques such as shearing, laser cutting, plasma cutting, or water jet cutting. Each method ensures dimensional accuracy and clean edge finishes for optimal part quality.

Press brakes and specialized bending machines form sheet metal into precise angles and shapes. Accurate control of bending force and angle is critical to prevent material deformation or cracking while achieving the target geometry.

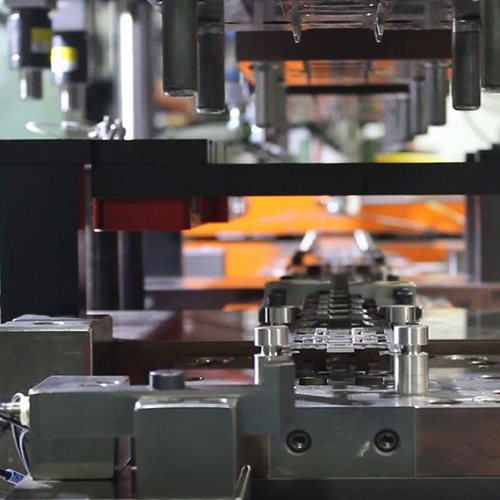

Stamping transforms sheet metal into precision parts through high-speed punching, bending, and forming using custom dies, enabling mass production of complex components with ±0.1mm tolerances for automotive, electronics, and industrial applications.

Various welding methods like spot welding, MIG, TIG, and seam welding are employed to permanently fuse sheet metal components. These processes create high-strength bonds that meet rigorous durability requirements for industrial applications.

YANGLI Hydraulic Swing Beam Shear

Max.stroke: 2500mm

Tolerance: ±0.01mm

1 Machine

CNC tube bending machine

Max.stroke: 3000mm

Tolerance: ±0.01mm

1 Machine

OSM press brake

Max.stroke: 100mm

Tolerance: ±0.05mm

1 Machine

OSM press brake

Max.stroke: 100mm

Tolerance: ±0.05mm

1 Machine

| Material Thickness | Typical Tolerance |

| Up to 0.5 mm | ± 0.05 mm |

| 0.5 mm-2.0 mm | ± 0.1 mm |

| 2.0 mm -5.0 mm | ± 0.15 mm |

| 5.0 mm-10.0 mm | ± 0.2 mm |

| 10.0 mm and above | ± 0.3 mm |

| Tolerances | |

| Forming and Bending: | +/- 0.4 mm |

| Bend to hole or feature: | +/- 0.2 mm |

| Linear dimensions excluding locations to bend | +/- 0.1 mm |

| Diameters with inserts | +/- 0.06 mm |

| Angularity | +/- 2 degrees |

| Surface roughness | +/- 3.2 micrometers |

| Countersink Tolerances | |

| Machined countersink major diameter | +/- 0.254 mm |

| Machined countersink minor diameter | 2/3 thickness |

| Formed countersink major diameter | +/- 0.381 mm |

| Formed countersink minor diameter | +/- 0.381 mm |

| Material Thickness | Typical Tolerance |

| Up to 0.5 mm | ± 0.05 mm |

| 0.5 mm-2.0 mm | ± 0.1 mm |

| 2.0 mm -5.0 mm | ± 0.15 mm |

| 5.0 mm-10.0 mm | ± 0.2 mm |

| 10.0 mm and above | ± 0.3 mm |

| Tolerances | |

| Forming and Bending: | +/- 0.4 mm |

| Bend to hole or feature: | +/- 0.2 mm |

| Linear dimensions excluding locations to bend | +/- 0.1 mm |

| Diameters with inserts | +/- 0.06 mm |

| Angularity | +/- 2 degrees |

| Surface roughness | +/- 3.2 micrometers |

| Countersink Tolerances | |

| Machined countersink major diameter | +/- 0.254 mm |

| Machined countersink minor diameter | 2/3 thickness |

| Formed countersink major diameter | +/- 0.381 mm |

| Formed countersink minor diameter | +/- 0.381 mm |