Our versatility to forge products in our forge hammers and presses, up to 1200T.

And the images in the article are taken from real scenes in our own forging factory.

Make the forging mold according to the drawings

Cutting the raw material

Send the raw material into the heating furnace for heating

Heat the mold

Slightly shape the preheated raw material (this step is not necessary and depends on the shape of the workpiece)

Apply mold release oil and forge the raw material into a billet

Trim the edges of the forged parts

Finish the rough workpiece through trimming or post CNC machining

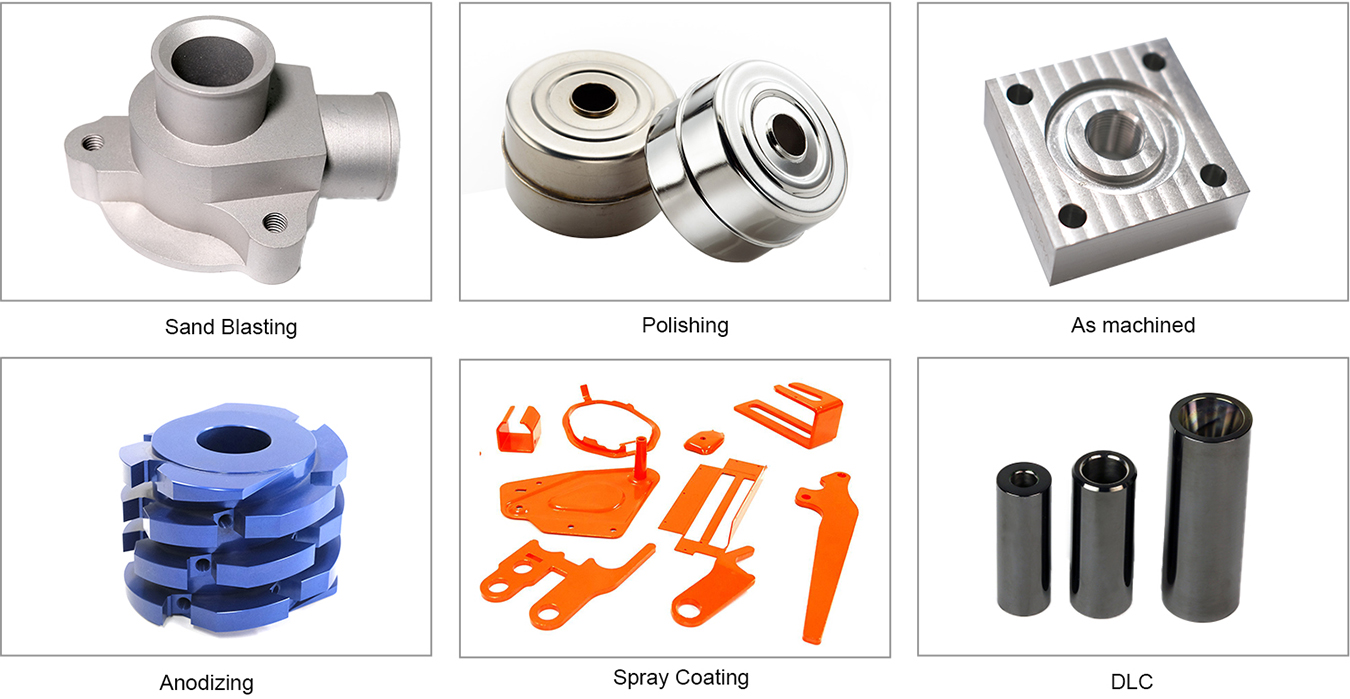

Sandblasting (surface treatment according to customer requirements)

Pack and ship the finished forging product